Loaded Strut Assembly vs Bare Strut

Choosing the Right Part

When it’s time to replace a strut, selecting the right replacement part is an important first step of the repair job. Depending on your application, you may have the choice between a strut assembly or a bare strut. What is the difference between a strut assembly and a bare strut? Which part is the right one for your repair?

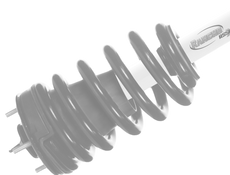

What is a Strut Assembly?

An all-in-one solution, a strut assembly includes everything needed for a strut repair. Also called a loaded strut assembly, a complete assembly includes:

- Upper strut mount

-

Strut bumper and boot

-

Spring seat

-

Insulators

-

Coil spring

Advantages of a Complete Strut Assembly

-

No Special Equipment Needed – By including a coil spring, no spring compressor is needed. Simple bolt-on installation makes it an easy repair for auto technicians and DIYers alike.

-

Convenience – With everything needed for the repair in a single component, a strut assembly means you don’t have to source other parts.

-

All New Components – With all new components, you don’t have to worry about the coil spring or any other part wearing out before your new strut does.

-

Quicker and Easier Repair – From removing the old strut to installing the new part, a strutassembly is quicker and easier to install. For those in the Rust Belt, you don’t have to worry about having a coil spring or other part being difficult to remove because of rust and corrosion.With the time savings, you’ll be able to complete more repair jobs.

-

Restores Performance – Using a strut assembly restores the vehicle to factory ride height toimprove steering and maintain vehicle control.

Disadvantages of a Loaded Strut Assembly

-

More Expensive – Because it has more components, a complete strut assembly is typically more expensive than a bare strut. However, the extra cost is likely balanced out by the time saved on the repair.

-

Limited Coverage – Compared to a traditional strut, there is less coverage for loaded strut assemblies

What is a Bare Strut?

Advantages of an Unloaded Strut

-

Cheaper – A bare strut is typically less expensive than a loaded strut since it doesn’t come with extra components.

-

Availability – Available for a wide variety of applications, unloaded struts have extensive coverage.

-

Customization – If you want to reuse the coil springs, mount and other components, a bare strut allows you to replace just the part you need to.

Disadvantages of a Bare Strut

-

Special Equipment Required – Because the strut has to be rebuilt, a spring compressor is needed. While this type of equipment is found in most shops, it isn’t something that a DIYer would typically have.

- Time Consuming – Rebuilding the strut adds time to the repair process.

Points of Consideration

-

Condition of Springs – Inspect the spring for cracks or damage. While springs can last longer than struts, rust and corrosion can cause them to prematurely fail. In addition, springs can sag, which can lead to diminished performance. Check the ride height to ensure that it is within specifications, and if the spring is out of spec, then a complete strut assembly might be a good choice.

-

Access to Specialized Tools – If you don’t have access to a spring compressor, going with a loaded strut assembly can take away the hassle of renting this piece of specialized equipment. This can be helpful especially for DIYers who aren’t likely to have a spring compressor in their garage.

Rancho® Strut Assemblies and Struts

Learn more about performance shocks, find your performance suspension part, or find where to buy your shock or suspension part today.

The content in this article is for informational purposes only. You should consult with a certified technician or mechanic if you have questions relating to any of the topics covered herein. Tenneco will not be liable for any loss or damage caused by your reliance on any content.